Continuous formwork with polystyrene foam (ICF) - the future of reliable and comfortable houses

Every homeowner dreams of spending his money on himself and his family. Spending on heating, air conditioning, light, and water is a dire necessity. The less we spend on keeping the house, the more money we have left on other pleasant things. That's why we want to have a place that has low maintenance costs.

A large arched window in a monolithic house.

It is easy to create arched openings in walls with insulated concrete formwork.

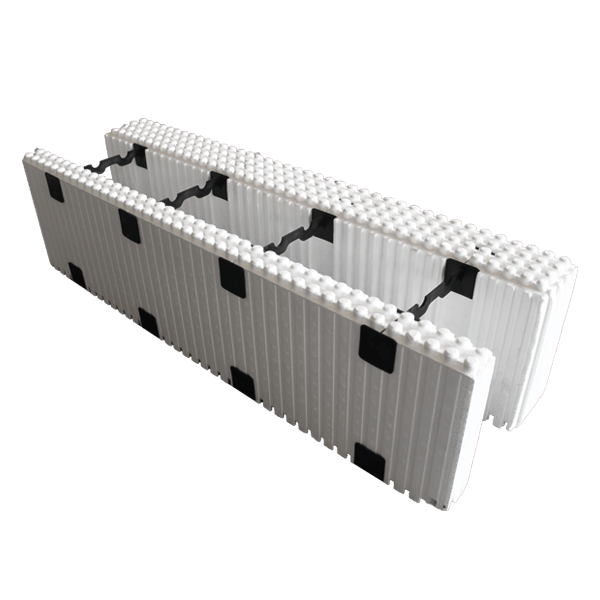

Scientific achievements allow producing new effective building materials. These materials will enable us to build a house both cheaply and efficiently. To the time-tested concrete and steel, we have added foam heat insulation. Insulators based on polystyrene and polyurethane have a thermal conductivity coefficient below 0.045 W/m*K. They can be produced in different densities. This has made it possible to create an innovative product - formwork combined with heat insulation - Insulated concrete formwork (ICF).

The formwork is produced in two ways: by extrusion and cutting. The first method is more expensive, but it can have any form of formwork. The fixed formwork is produced in small blocks. The two walls of the blocks are connected using moulded or separate plastic ties. The moulded block is usually cheaper. But it takes more space when transported. Therefore, the low cost at first glance may not be so intense.

Removable plastic ties are equipped with slots for laying horizontal reinforcement steel. There is no need for binding wire, which speeds up the formwork assembly process. In addition, the ends of the plastic ties serve as furring strips for attaching dry plaster or other finishing materials. This also speeds up the process of finishing the house.

Wall assembling and pouring

The assembly of insulated concrete formwork takes only a few days, depending on the size of the project. The concrete is then poured into the formwork using a concrete boom pump. Usually, one floor can be running in one day. When casting in this way, the contractor walks with a concrete pipe around the perimeter of the future house and pours up to 3 feet of concrete. Не is followed by a worker with a vibrator for proper compaction of fresh concrete. When casting in this way, the contractor walks with a concrete hose around the perimeter of the future house and pours up to 3 feet of concrete. This is followed by a worker with a vibrator for proper compaction of fresh concrete. If the walls are up to 12 feet high, the entire concrete mix will be poured in three cycles.

Sometimes it is not possible to rent a concrete pump with a boom. Sometimes the concrete pump cannot drive up to the construction site. Then it is possible to rent a mini concrete mixer and make the concrete mix on site. In this case, the concrete formwork blocks are assembled to a height of about 3 feet. Vertical reinforcement is installed to the total size of the wall. The concrete is poured from small containers.

The last method has several disadvantages.

- Cold seams are formed.

- The ends of the vertical rebar interfere with the pouring of concrete.

- There is no guarantee that the wall will turn out perfectly flat.

- The construction time is rising.

But there are also positive aspects. It is possible to use less dense concrete formwork, which is cheaper. There is no need to pay for a concrete pump. You can build in rural areas.

The wall construction process may be different, but the advantages over other construction methods are the same in both cases.

One of the laborious steps in constructing a brick or block concrete house is the production of door and window openings.

Windows and Doors Openings

It is necessary to buy metal or concrete lintels or make them from the concrete mixture on-site using formwork.

It is required to insulate the external openings in the future.

In the construction of ICF creation and insulation of openings is integrated into the overall wall assembly process. Install additional reinforcement around the doors and make temporary formwork from planks. The ends are closed with polystyrene foam plugs. The easy forming of the aperture allows a wide variety of shapes of windows and doors.

Various structural methods are used to create the floor slabs between the stories. These can be

- wooden trusses;

- I-beams;

- hollow-core prefabricated panels;

- monolithic concrete floors with or without insulated concrete formwork.

When using ICF to form a concrete floor, a water underfloor heating system can be installed simultaneously.

Laying of power networks and pipes

Installing sockets and pulling electrical wires is painstaking work. Doing this on walls made of concrete blocks or bricks is quite tricky. It is necessary to continue the kilometres of the shaft and drill dozens of holes for sockets and switches. Unlike brick houses with insulated concrete formwork, this can be done with a conventional hot knife or a simple electric tool heating the string. A chain saw with a cutting depth control will also be helpful for this purpose.

Some sockets can be installed even before the formwork is filled in. Water and sewage pipes and fixings for heavy devices can also be installed before the formwork is poured.

Additional advantages of ICF houses

- The ICF allows an effortless combination of wall, floor and roof structures made of different building materials. For example, internal walls, floors, and roofs can be made of wood sticks. The frame structures weigh less and reduce the load on the foundation and soil.

- The Wall thickness of insulated concrete formwork with higher thermal insulation is more minor than bricks and aerated concrete blocks. This makes it possible to obtain a more extensive internal area with the exact dimensions of the building.

- In an ICF house, the wall is thicker than in a conventional home, but it is easier to achieve good airtightness.

- ICF walls are not subject to rotting caused by high humidity.

- ICF walls are not exposed to destruction in areas with strong winds, floods, and termites.

- Some researchers mention a lower risk of fire to the inhabitants of the house. In my opinion, this is not always true. Much depends on the structure of the roof, floor, and interior walls. However, the insurance costs for concrete houses will be much lower than a wooden frame house of a similar size.

The choice of building design depends mainly on the availability of building materials in your area, the builders' professional skills, and local traditions. However, if insulated concrete formwork is available in your area, building a house from it is the best solution. If you are interested in the construction technology with permanent formwork, you can read the article: "Casting concrete in a permanent formwork".